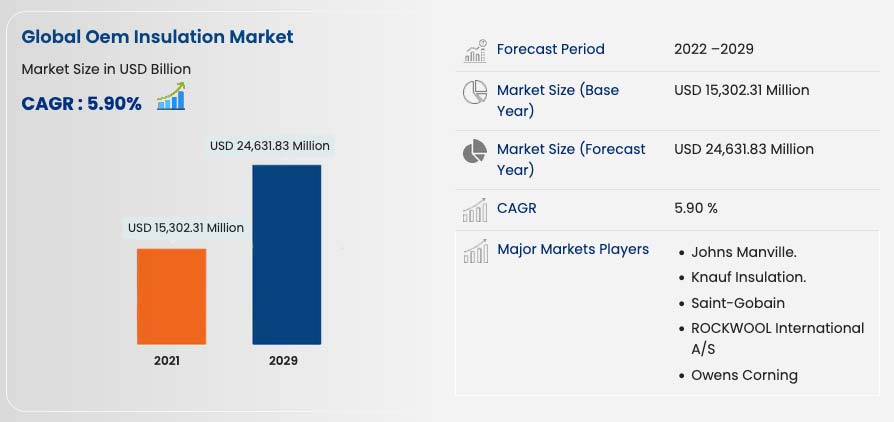

Insulation materials are no longer passive add-ons; they are performance-critical assets shaping OEM supply chains worldwide. From EV battery safety to defence-grade fire protection, export-ready insulation materials now sit at the core of engineering reliability. The global OEM insulation market, valued at USD 15.3 billion in 2022, is projected to reach USD 24.6 billion by 2030, growing at a 5.9% CAGR. At the same time, India is scaling faster at home—the industrial insulation market is expected to rise from USD 266.2 million in 2023 to USD 465.8 million by 2030, at an impressive 8.3% CAGR

With more than 30 years of experience in the broadcast media industry and now as Co-Founder of TrendVisionz. I’ve worked closely with businesses and OEM companies across diverse sectors. This journey has given me a front-row view of how technical materials, once overlooked, are shaping industries, and how India is emerging as a reliable sourcing destination.

This article explores India’s position in the global OEM insulation landscape. We’ll examine market growth, export readiness, compliance standards, and case studies that highlight how insulation materials are defining the future of EV and defence supply chains.

Also Read:

- Smart Insulation and Energy Efficiency Tips for Industry

- Every Layer Counts: Future-Proofing with Multi-Layer Insulation Technology

Why Insulation Materials Matter in Global OEM Supply Chains

Insulation materials have evolved from cost items to engineered risk controls embedded into OEM design logic. In EV battery systems, they serve as critical module barriers that limit thermal runaway propagation. A single cell failure no longer cascading into full-pack meltdown. In aerospace and defence, materials must prequalify to fire, smoke, and toxicity (FST) standards like FAR 25.853 before suppliers even get on bidding lists.

With transportation projected to be the fastest-growing end use in the OEM insulation market. Expected to reach USD 24.8 billion by 2030 from USD 17.99 billion in 2024 (CAGR 5.5%). Insulation materials are shifting from peripheral to central in system engineering.

Where insulation materials move the needle

- Safety: propagation barriers, fire resistance, and electrical isolation that protect systems under abuse conditions.

- Compliance: documented quality via PPAP for automotive and FST/FAR 25.853 regimes for aircraft interiors.

Why are insulation materials essential for EV and Defence OEMs?

Because they combine thermal and acoustic insulation with verified compliance. In EVs, properly specified barriers reduce heat release and help prevent cell-to-cell propagation. In aircraft and defence cabins, only materials that pass FAR 25.853/FST testing are acceptable—making certified insulation a gate to sourcing approval.

Key insight: For OEMs, insulation is no longer background; it’s the engineered interface between safety, performance, and the compliance frameworks that secure program approval.

India’s Position in the Insulation Export Market

India’s insulation market is growing faster than the global average. Valued at USD 266.2 million in 2023, it is expected to reach USD 465.8 million by 2030. This 8.3% CAGR reflects strong domestic demand and scaling capacity.

Local growth supports export-readiness. Indian manufacturers are not only meeting internal needs but also preparing to supply global OEM companies. The industry is already delivering high-temperature composites, mica sheets, and ceramic fibres for complex applications.

Key Insight: Domestic momentum gives India resilience. By building capacity at home, insulation material exports can expand abroad with fewer risks, creating a stronger base for Indian manufacturing exports and global supply chain resilience.

Export-Ready Insulation for EV and Defence OEMs

OEMs in EV and defence platforms cannot compromise on insulation. Safety, compliance, and durability are non-negotiable. India is stepping into this space with solutions that are already reaching international markets.

EV Insulation Innovations

Insulation is critical in EV batteries, acting as a barrier to thermal runaway. Indian firms are now part of this global supply chain.

- Murugappa Morgan Thermal Ceramics (MMTCL), a joint venture with Morgan Advanced Materials (UK), exports Superwool® EST and microporous insulation used in EV battery protection for European OEMs.

- Darq India produces aerogel thermal insulation1 pads for EV batteries that are marketed internationally. These pads combine fire resistance, ultra-low thermal conductivity, and lightweight design, aligning with OEM safety standards abroad.

- PBM Insulations, with three decades of experience in automotive and industrial insulation, supplies OEM-grade thermal and acoustic solutions. Its zero-PPM plants in Aligarh and Vapi and IATF-certified operations position PBM to deliver export-ready EV insulation mats and composite jackets to international OEMs in the automotive and mobility sectors.

Defence-Grade Insulation

Defence OEMs demand materials that pass strict certifications such as AS 9100 for quality and FAR 25.853 for fire, smoke, and toxicity. Indian suppliers are responding with advanced materials like hydrophobic melamine foam and PEEK composites, now evaluated in aerospace interiors and naval platforms.

India’s defence exports reflect this readiness. From just USD 81 million in FY14, defence exports, including insulation and composite systems, have climbed to USD 2.8 billion in FY25, supplying global OEMs in aerospace and shipbuilding With some good Indian manufacturers already contributing to global OEM supply chains. India’s insulation sector is proving its ability to deliver high-performance, compliant, and export-ready solutions for EV and defence platforms.

Compliance, Sustainability, and the Road Ahead for Indian Insulation

Compliance and sustainability define success in today’s OEM supply chains. From IATF and AS 9100 certifications to RoHS and ESG commitments, insulation manufacturers in India must meet these standards to stay export-ready and globally competitive.

Why this matters for OEM sourcing:

- Automotive: IATF 16949 and PPAP are mandatory for suppliers.

- Defence/Aerospace: AS 9100 and AS 9120 certifications ensure reliability.

- Environmental: RoHS and REACH make insulation “export-ready by design.”

- Sustainability: Indian firms are investing in green insulation material, recyclable processes, and ESG alignment.

Recent studies also highlight the global shift toward sustainable thermal and acoustic insulation from waste sources (Ouda et al., 2025)2

Why Compliance and Sustainability Define India’s OEM Readiness

Compliance is no longer optional; it is the entry ticket to global OEM contracts. For automotive suppliers, meeting IATF and PPAP demonstrates zero-defect readiness. In defence and aerospace, AS 9100 proves that manufacturers can meet the most rigorous quality benchmarks.

Environmental compliance strengthens this advantage. By producing sustainable insulation in India, with lower carbon output and recyclable formats, manufacturers not only meet RoHS and REACH directives but also appeal to OEMs with ESG mandates.

Policy is driving this shift. The government’s PLI scheme for Advanced Automotive Technology (₹25,938 crore) is incentivizing advanced material production. Joint ventures like MMTCL are scaling high-performance composites, while companies such as PBM Insulations use IATF-certified plants to deliver export-ready solutions.

What challenges limit India’s insulation export growth?

High logistics costs, uneven R&D, and global competition remain hurdles. Investing in AI-driven quality control and advanced composites is key to sustaining export growth.

Compliance and sustainability are no longer just checkboxes. With government support and industry innovation, India’s insulation solutions are on track to become essential components in global OEM growth.

Case Studies of Indian Insulation in OEM Markets

Real-world applications show how Indian insulation is gaining global trust. From automotive to defence and energy, export-ready solutions are proving their value in meeting international standards.

- Duratuf Insulating Mats exports more than 50% of its insulating mats to countries across five continents. Insulating

- HIC Universal manufactures insulating rubber mats and sheets in India and claims exports to Europe, USA, UK, China, UAE, etc. hic-india.com

- India’s defence exports in FY25 reached ₹23,622 crore (~USD 2.8 billion), which includes components and subsystems—this suggests defence-related products (possibly including insulation/composites) are being exported.

What is an OEM Company and How Does it Work?

An OEM company designs and manufactures parts or products used by other brands in their final goods. OEM parts ensure compatibility, reliability, and scalability. In insulation, OEMs depend on certified suppliers to guarantee safety and performance.

Is OEM High Quality?

Yes. OEM quality is higher because parts follow exact design specifications. In insulation, OEM-approved products meet zero-defect standards, certified performance, and long-term durability for automotive, EV, and defence applications.

Key Lesson: These case studies show that India’s insulation materials are not just export-ready but already part of global OEM supply chains—demonstrating quality, compliance, and the potential for long-term partnerships.

Also Read:

- Fibre Insulation in Defence: The Backbone of India’s Modern Military Tech

- Types of Insulation Materials and Their Applications: A Complete Guide for Professionals

FAQ: Insulation Materials

What are the risks of buying OEM products?

Risks include counterfeit or uncertified items, poor quality control, and supply delays. Working with verified OEM suppliers reduces these risks by ensuring compliance, durability, and safety across applications.

Why is India preferred for OEM insulation exports?

India offers certified manufacturing, cost efficiency, and advanced materials. With IATF- and AS-certified plants, plus government-backed incentives, Indian insulation exports deliver reliable, sustainable, and export-ready solutions to global OEMs.

What certifications are essential for insulation suppliers?

Key certifications include IATF 16949 and PPAP for automotive, AS 9100/9120 for defence and aerospace, and RoHS/REACH for environmental compliance. These prove suppliers meet zero-defect, safety, and sustainability standards.

Conclusion

India’s insulation materials sector is moving from domestic strength to global leadership. With proven capacity, advanced materials, and credible exports, Indian suppliers are now integral to global OEM supply chains.

Their advantage lies in combining cost efficiency with strict compliance frameworks such as IATF 16949, AS 9100, and RoHS. Equally important is the industry’s focus on sustainability, delivering green insulation materials and recyclable solutions that align with ESG mandates.

At TrendVisionz, we track these developments closely, drawing on decades of industry experience and our work with OEMs across sectors. For global manufacturers, this signals more than a sourcing option—it’s a strategic partnership. India is ready to supply zero-defect, compliant, and future-ready insulation solutions for the world.

Additional Resource

- Kumar, Mukesh & Ahmad, Rabnawaz & Arif, Rashique. (2023). Emerging Trends In Thermal Insulation Materials And Techniques. 44. 1001-4055. ↩︎

- Ouda, M., Abu Sanad, A. A., Abdelaal, A., Krishna, A., Kandah, M., & Kurdi, J. (2025). A Comprehensive Review of Sustainable Thermal and Acoustic Insulation Materials from Various Waste Sources. Buildings, 15(16), 2876. https://doi.org/10.3390/buildings15162876 ↩︎

Stay Connected with Me:

Anuj Mahajan is a Mass Communication Specialist, ICF-ACC Certified Coach, Corporate Trainer, Motivational Speaker, NLP Life Coach, Filmmaker, and Author. With 30+ years in media, marketing, and leadership coaching, he unites storytelling, mindfulness, and digital transformation.

- Explore my work: Nuteq Entertainment | TrendVisionz | Author Profile

- Read our newsletters: Transforming Lives | BizTech Chronicle | Nuteq Newsline

- Guest writer: BizCatalyst360 | Praja Today

- Books: Go Mindfulness: Practices for Professionals Coached

- Join the community: LinkedIn Group – Digital Marketing & Content Creation World

- Connect with me: LinkedIn | Twitter | #StoryforBusiness

- Share your review: Leave your review on Google — your feedback helps us grow.

- Listen on Spotify: Leadership Podcast | Guided NLP (7 Episodes) | Daily Motivation – 21 Episodes

Believe. Practice. Perform. Let’s create impact together.

✍️ A Note from the Editor

Independent storytelling thrives with you. Contribute $15/month via PayPal or email us at anujmahajan@trendvisionz.com. [Guest write for us — Free or Paid.]

2 comments

Excellent roundup of resources — saved me hours of searching.

[…] for Urban Living and Busy Lifestyles Global Education Trends: Student Immersion Programs Export-Ready Insulation Materials: India’s Global OEM Advantage Mobile-First Indexing: What You Should Know Financial Independence in the Digital Age with […]

Comments are closed.