In an era where industries are pushing the limits of performance, insulation is no longer just about controlling heat. It is about engineering precision. According to a recent industry report, the global insulation market is projected to reach USD 86.7 billion by 2033. Multi-layer insulation systems leading innovation across sectors like electric vehicles (EVs), defence, and industrial equipment.

As Co-Founder of TrendVisionz, I’ve partnered with some of India’s most forward-thinking businesses. Many of them now look for insulation solutions that are effective and future-ready. Through our insights we endeavour to build a complete picture for professionals looking to stay ahead in the insulation industry.

In 2025 and beyond, companies are moving from basic thermal protection to multi-layer insulation systems. These systems offer thermal, acoustic, and fire-resistant benefits in one smart design.

Unlike single-material solutions, multi-layer insulation combines multiple engineered layers. Foil, felt, ceramic, and aerogel are engineered to serve specific functional roles. This article explores the science behind this innovation, the materials involved, and how this engineered approach is solving real-world insulation challenges.

Also Read:

- Export-Ready Insulation Materials: India’s Global OEM Advantage

- Fibre Insulation in Defence: The Backbone of India’s Modern Military Tech

- Smart Insulation and Energy Efficiency Tips for Industry

Multi-Layer Insulation: Breaking Down the Stack

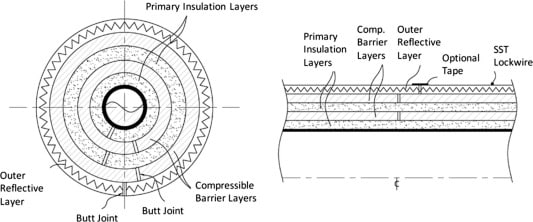

Multi-layer insulation is a system made by combining different insulation materials into layers. Each layer plays a specific role in managing heat, sound, or vibration. This approach is also known as stack-up insulation, especially in industries where custom engineering is required.

What Is Multi-Layer Insulation?

This is a technique where two or more materials are stacked together to create a barrier that resists heat, sound, or mechanical stress. This structure is often called a heat-resistant composite stack.

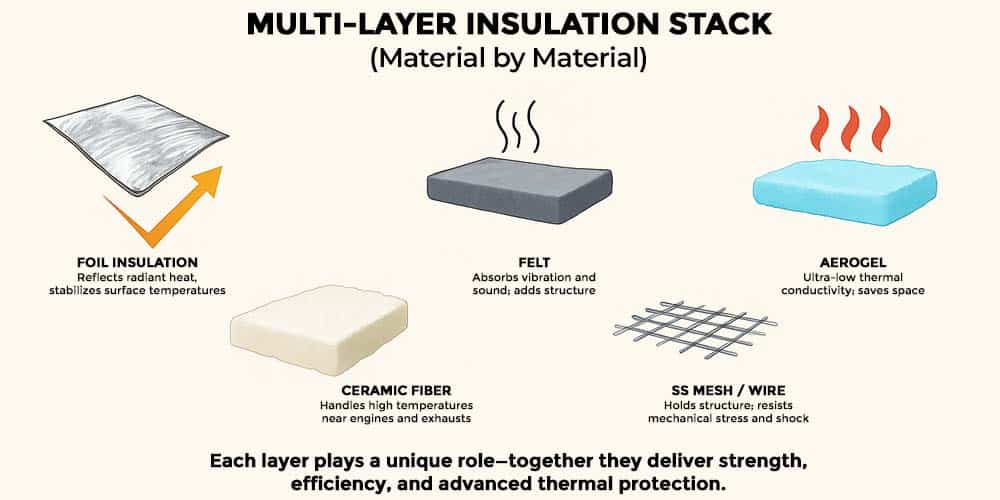

Each material in a multi-layer system serves a unique function:

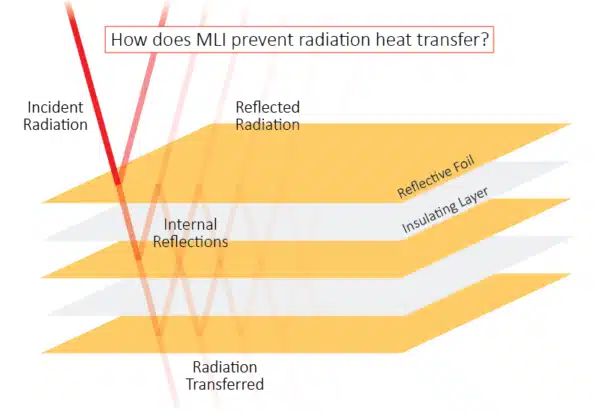

- Foil: Functions as a reflective surface that bounces radiant heat away

- Felt: Provides vibration control and acoustic dampening

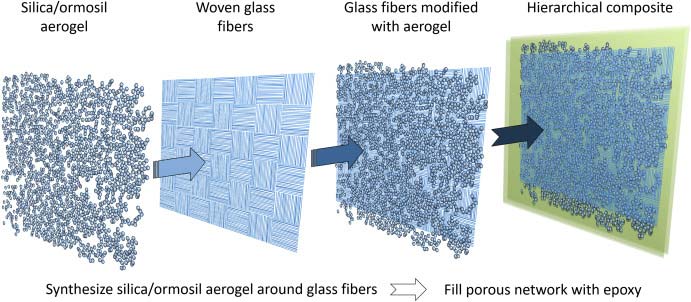

- Aerogel: Offers ultra-low thermal conductivity

- Ceramic fiber: Withstands extreme heat and resists fire

- Mesh or SS layers: Add structure and form to the stack

By layering these materials, the system becomes stronger, more durable, and more adaptable to harsh environments.

The layered approach also adds redundancy. If one layer fails, the remaining layers continue to provide protection and maintain system performance. This makes composite insulation a trusted method for applications in electric vehicles, industrial machinery, and defence-grade platforms.

The Science Behind Each Layer: Materials That Matter

In multi-layer insulation, every material is selected for a specific role. Together, these layers work to create a powerful system that protects against heat, moisture, vibration, and structural stress. Each layer brings its own strength, helping the system perform in even the most extreme conditions.

These insulation systems are engineered with purpose. The selection of materials is based on performance goals. Each layer has a defined function.

Here’s a breakdown of the most common materials used in multi-layer insulation systems:

- Foil insulation: Acts as a radiant barrier. It reflects heat and helps control surface temperatures.

- Felt: Adds structure and softens vibration. It also acts as an acoustic buffer in noisy environments.

- Aerogel insulation layers: Known for ultra-low thermal conductivity. It helps retain temperature control in limited space.

- Ceramic fiber: Provides high heat resistance. Often used near engines or exhaust systems.

- SS mesh or wire: Adds structural integrity. It holds the layers in place and helps resist mechanical shock.

These materials have been proven in real-world applications. In defence environments, for example, insulation systems often rely on ceramic fiber and SS mesh to withstand extreme heat, vibration, and impact. These combinations are designed to perform under battlefield conditions and mission-critical operations.

The selection of thermal barrier materials depends on the unique demands of each system. Designers consider shape constraints, risk of water exposure, exposure to vibration, and fire safety. The goal is to create a system that lasts longer, performs better, and meets safety standards.

Designed for Application: From EVs to Industrial Units

Multi-layer insulation is never one-size-fits-all. Its real strength lies in how it can be tailored to meet specific application needs. Engineers develop custom insulation assemblies depending on the use case. Each industry brings different challenges—heat, vibration, moisture, and space constraints. The insulation must be designed to match those conditions.

Insulation for Electric Vehicles

Insulation is critical in EV for thermal safety and battery life. Battery packs produce heat during both charging and use. A multi-layered system used in one EV assembly plant in India combines aerogel for heat control, felt for cushioning, and foil for radiant protection. This helps reduce fire risk and extend battery performance.

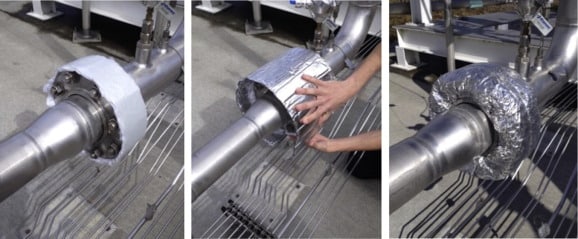

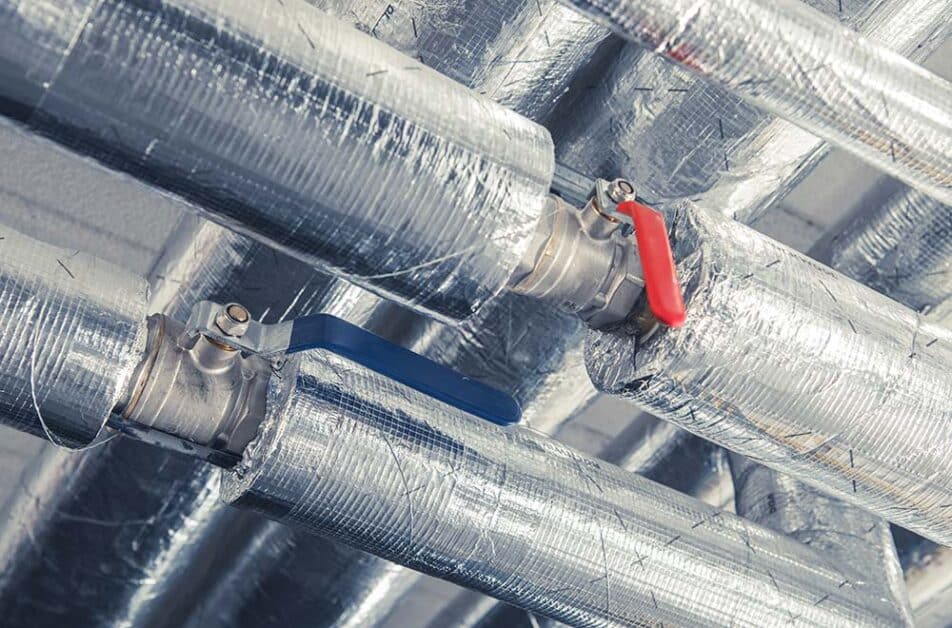

Thermal Insulation for Industrial Use

In most modern industries, insulation must withstand high temperatures, humidity, and continuous operation. Many facilities use composite stacks with foil, glass wool, and non-woven felt. These systems prevent energy loss and keep surface temperatures safe. One Indian manufacturing unit used this configuration on steam pipelines to reduce heat loss and improve energy efficiency.

Custom Insulation Assemblies in Defence Vehicles

Defence vehicles need lightweight but durable insulation that can handle vibration and high heat. A common multi-layer design includes ceramic fiber, stitched felt, and SS mesh. In Indian military-grade vehicles, this configuration is used in engine compartments and exhaust systems. It helps manage heat without adding bulk or weight.

Multi-layer insulation is successful because it adapts to real-world needs. Each layer is chosen for a reason, and together, they provide reliable performance in the most demanding environments.

How It’s Engineered: Simulation, Prototyping and Testing

The development of multi-layer insulation systems is a precise and technical process. It combines software-based design with real-world testing. This ensures each stack performs well in demanding environments.

What does industrial insulation design involve?

Leading insulation manufacturers follow a structured engineering stack that includes:

- CAD-based software tools like SolidWorks, Prolog, and Simu-Therm. These simulate how heat, sound, and vibration move through different layers.

- Layer optimization for thermal, acoustic, and mechanical needs. Each layer is adjusts to suit specific temperature and load conditions.

- Lab testing of materials and complete assemblies. Common tests include:

- Limiting Oxygen Index (LOI)

- Shrinkage tolerance

- Moisture retention capacity

This process helps deliver advanced insulation solutions that are not just functional, but reliable over time.

More importantly, the industry is moving toward application-specific insulation engineering. Every insulation stack has specific use case in mind. Whether for electric vehicles, defence platforms, or industrial units.

Instead of general-purpose materials, the focus is now on designing for purpose, not just performance.

Multi-Layer vs Single-Material Insulation: The Value Shift

As industries evolve, so do their insulation needs. Traditional systems used one material to solve one problem. But that is no longer enough. Multi-layer insulation is now setting the standard across electric vehicles, defence, and manufacturing sectors.

Why is high-performance insulation gaining ground

Multi-layer insulation is replacing single-material systems for three key reasons:

- Better performance

Each layer serves a function. Together, they offer protection against heat, fire, vibration, and noise. - Longer lifespan

If one layer degrades, others still perform. This adds durability and reduces maintenance. - Environmental benefits

Systems designed with recyclable or low-emission materials help meet sustainability goals. They also support energy savings by limiting heat loss.

These improvements make multi-layer designs a true energy-efficient insulation system. The added durability and safety also reduce long-term operational costs.

OEMs are responding to these advantages. Many are shifting from basic thermal wraps to intelligent stack-ups. This shift drives demand for smarter, safer, and more sustainable products.

The result is clear. High-performance insulation is no longer optional. It is a strategic choice that improves both system value and user safety.

Inside the Stack – Real Industry Insulation Solutions at Work

Multi-layer insulation is not just a concept. It is in use across industries in products that must perform in high-stress environments. Design of each stack is carefully to match the demands of the specific application.

What does a real-world stack-up insulation system look like

Here are three examples of how composite insulation is in use today:

1️⃣ Electric Vehicles

- Stack: Aerogel + Felt + Foil

- Use: Battery thermal protection

- Specs: Thin profile under 10 mm, up to 200°C temperature resistance

- Why: Offers fire resistance, low thermal conductivity, and vibration absorption

2️⃣ Defence Vehicles

- Stack: Ceramic fiber + SS mesh + Stitched felt

- Use: Engine compartment and exhaust systems

- Specs: Tolerates temperatures above 800°C, reinforced for shock and vibration

- Why: Ensures safety under battlefield conditions without adding weight

3️⃣ Industrial Units

- Stack: Glass wool + Aluminium foil + Non-woven felt

- Use: Steam pipelines and heavy machinery

- Specs: Moderate thickness, moisture-resistant, operates in humid environments

- Why: Minimizes thermal loss and helps improve energy efficiency over time.

These tailored insulation assemblies demonstrate how stack-up insulation effectively addresses complex, real-world performance demands. The materials selection is not just for function, but for reliability, safety, and adaptability.

The Road Ahead: Innovations and Future of Insulation Systems

The insulation industry is evolving into a new era of innovation and advanced material engineering. As performance demands rise, so do expectations around safety, sustainability, and efficiency. Future insulation systems will be more intelligent, environmentally friendly, and precisely designed for specific applications.

What’s next in advanced insulation solutions

Ongoing research and development focusses on:

- Smart layers designed to respond instantly to changing temperatures

- Self-repairing materials that recover insulation function after wear or damage

- AI-assisted design tools that reduce prototyping time and improve accuracy

Alongside performance improvements, there is a strong push toward sustainability. Manufacturers are now investing in:

- Recyclable insulation components

- Low-VOC adhesives and materials

- Processes that reduce production waste

These trends align with global ESG goals. Companies deliver insulation systems that is both high performing and responsible.

To guide innovation, engineers compare1 multiple insulation technologies. Each with unique strengths and limitations. The graphic below shows how multi-layer insulation stacks up against other advanced materials.

As these advancements continue, the focus will shift toward building application-specific insulation engineering into the core of every design. Whether for electric vehicles, aerospace, or industrial units, every layer will serve a defined purpose.

The future of insulation is not just about resisting heat. It is about creating energy-efficient insulation systems that perform better, last longer, and support a more sustainable world.

Also Read:

- Return on Ad Spend (ROAS): Boost Profits from Every Marketing Spent

- Digital Transformation in Banking: How Banks Are Evolving

FAQ: Multi-Layer Insulation

What is the purpose of multi-layer insulation?

Multi-layer insulation is designed to combine materials like foil, felt, ceramic, and aerogel in layered form. Each layer serves a purpose—thermal resistance, vibration control, or fire safety. The goal is to build a durable, high-performance barrier for electric vehicles, defence systems, and industrial machines.

How is multi-layer insulation used in different industries?

In electric vehicles, it protects batteries from heat and extends performance. While in defence, it handles high temperatures and shock in engine zones. Morevover in factories, it reduces energy loss and improves equipment safety. These are custom insulation assemblies designed for real-world conditions.

What is MLI in space?

In space applications, multi-layer insulation (MLI) refers to thin layers of reflective materials used to control extreme temperatures in spacecraft. These vacuum-optimized layers reflect radiation and insulate satellites and modules. While the structure is similar, MLI in space serves a different purpose than composite insulation used in industries on Earth.

Conclusion

Multi-layer insulation has become essential in today’s engineering landscape. It addresses the growing need for safety, efficiency, and performance across industries. Each layer is selects for a reason. It makes the system stronger. From electric vehicles to defence and industrial units, these designs offer clear, measurable benefits.

The future of the planet earth lies in intelligent, dependable, and engineered insulation. Precision in material selection and stack design is not optional. It is time for OEMs and manufacturers to shift their mindset and start thinking layer-first. In modern insulation, every layer truly counts.

Stay ahead of evolving insulation trends and technology. Explore more expert insights at TrendVisionz—your trusted resource for industry-focused innovation.

Additional Resource:

- Zhang, Q., Huang, H., Lei, C., Liu, Y., & Li, W. (2025). Review of Lightweight, High-Temperature Thermal Insulation Materials for Aerospace. Materials, 18(10), 2383. https://doi.org/10.3390/ma18102383 ↩︎

Share your Review

Our Digital Imprints:

About the Author: Anuj Mahajan is a Mass Communication Specialist, ICF Certified Coach & Corporate Trainer. Motivational Speaker / NLP Lifecoach. With expertise spanning filmmaking, business coaching, motivational speaking, blog writing, and authoring, he embodies versatility and mastery across diverse fields.

Chief Operating Officer: Nuteq Entertainment Pvt Ltd, and Co-Founder: Trendvisionz – A Premier Digital Marketing Agency in India

Connect with with our Newsletters- Transforming Lives… Creating the magic. Just – Believe ~ Practice ~ Perform BizTech Chronicle… Navigating Tomorrow’s Tech Frontiers 🚀

Join my LinkedIn Group: Digital Marketing, Content Creation World Group

Follow me on Twitter or LinkedIn. Check out my website.

✍️ A Note from the Editor

At TrendVisionz, we craft each article with purpose—guided by research, passion, and the belief that storytelling can spark change. We’ve kept our content open and free for all. In the hindsight we believe knowledge should never be behind a paywall.

Creating quality digital content takes time, heart, and resources. We sincerely hope this article resonates with you. Thank you for your support. Even $10/month can help us keep producing content that informs, empowers, and uplifts.

💛 Support our work: You can contribute directly via PayPal or email us at anujmahajan@trendvisionz.com to set up your monthly support.

Thank you for believing in independent digital journalism. —Editor

11 comments

[…] Posts Every Layer Counts: Future-Proofing with Multi-Layer Insulation Technology Citizenship by Investment and Residency: The Rise of Global Indians in… Linen Luxe Meets […]

My smile looked healthier, boosting my confidence.

Where to See White Lions in Africa

Level Up Your Designs: Download Adobe Firefly 2025!

Save Time & Effort: Download Adobe Firefly 2025 Today!

Hi there to all, for the reason that I am genuinely keen of reading this website’s post to be updated on a regular basis. It carries pleasant stuff.

I truly appreciate your technique of writing a blog. I added it to my bookmark site list and will

we appreciate it

I just could not leave your web site before suggesting that I really enjoyed the standard information a person supply to your visitors Is gonna be again steadily in order to check up on new posts

[…] how multi-layer insulation systems are reshaping the way industries tackle heat, vibration, and reliability—layer by […]

You got a very superb website, Gladiolus I detected it through yahoo.

Comments are closed.