Every product we trust begins with someone who understands precision. In today’s manufacturing world, a single delay or design flaw can ripple across continents. According to Deloitte, over 70% of global manufacturers now view supplier reliability and transparency as critical to growth. That’s why OEM partnerships have evolved from transactional deals into strategic alliances rooted in measurable trust.

As a business strategist with over three decades of marketing and communication experience, I’ve seen how credibility, once a brand value, is now a business model. Companies no longer compete on price alone—they compete on reliability. Engineered trust has become the new quality standard, where data validation, certification, and collaboration define success.

This article explores how engineered trust and the emerging 360° OEM model are redefining global manufacturing partnerships. Creating an ecosystem where precision, accountability, and innovation work together to build enduring value.

Also Read:

- Europe Work Opportunities: Who Leads the New Job Wave?

- QS Rankings Explained: How Top Universities Are Ranked Worldwide

What Is a 360° OEM Model and Why It Matters

In my experience working with manufacturers across agri-tech, automobile, and skincare sectors, the most reliable OEM partnerships grow from collaboration, not compliance. A 360° OEM model brings that collaboration to life. It extends far beyond supplying components. It creates a unified workflow where design, engineering, validation, and service operate as one continuous process of reliability.

Indian OEM partnerships are moving beyond cost competitiveness to credibility competitiveness. Global clients now choose India not just for scale, but for consistency, certification, and co-innovation — FICCI Press Release

This evolution signals a deeper shift—India’s OEM landscape is no longer only about delivering capacity but about nurturing collaboration that builds trust and long-term value across global supply chains.

What types of OEM partnerships exist?

OEM partnerships vary in purpose and depth, depending on business goals and project scope. Some are built for long-term collaboration and innovation, while others focus on agility, specialization, and meeting immediate manufacturing or market needs. Partnership type plays a distinct role in shaping how businesses collaborate within the OEM ecosystem. Partnerships generally fall into two categories:

- Strategic partnerships: Long-term collaborations focused on mutual growth and innovation.

- Tactical partnerships: Short-term or project-based alliances designed for agility, specialization, and faster market response.

Together, these alliances create the foundation for a holistic approach to manufacturing excellence—one that connects design, delivery, and service into a seamless chain of accountability. This integrated framework is what defines the true essence of a 360° OEM model.

The Six Building Blocks of a 360° OEM Model

A complete 360° OEM framework combines six essential layers that hold the precision manufacturing ecosystem together:

- Design and engineering support for early compatibility and innovation

- Customization to meet specific market and client requirements

- Quality assurance and testing through verified validation cycles

- Certified manufacturing standards aligned with ISO compliance

- After-sales service that sustains long-term product reliability

- Licensing and brand alignment for transparency and trust

Each layer strengthens the design-to-delivery process, ensuring accountability at every stage.

Why It Builds Trust

Every step, from design validation to certified production, converts promises into measurable proof. When teams work transparently and standards stay consistent, engineering reliability becomes the real brand value. Across sectors, this approach turns complex supply chains into dependable, trusted manufacturing partnerships that customers can believe in.

Takeaway: A 360° OEM model connects design, engineering, certification, and service into one transparent process. It transforms fragmented supply lines into dependable ecosystems built on verified quality and predictable reliability.

How 360° OEM Differs from Traditional OEM Models

Traditional OEMs deliver parts. 360° OEMs deliver performance. Over the years, I’ve seen how this difference defines success. While traditional models focus on fulfilling an order, 360° OEM partnerships build collaboration from concept to delivery. They replace linear transactions with shared accountability, integrating design validation, testing, and certified manufacturing standards into every stage.

Comparison: Traditional OEM vs 360° OEM

Before we dive deeper, the following table highlights the fundamental differences between conventional OEM operations and the 360° OEM approach. It shows how modern supply chains evolve from product delivery to performance-driven partnerships.

| Aspect | Traditional OEM | 360° OEM |

| Scope | Component supply | Full-spectrum solutions covering design, testing, and after-sales |

| Partnership | Transactional | Strategic collaboration based on transparency and data sharing |

| Customization | Limited | High customization through co-development and simulation |

| Quality | QC checks after production | End-to-end assurance through proactive validation and certification |

| After-sales | Minimal involvement | Integrated technical and service support that extends reliability |

This shift creates value far beyond efficiency. When design, manufacturing, and service functions communicate in real time, quality becomes predictable and relationships grow stronger.

Takeaway: Moving from transactional supply to integrated co-innovation helps manufacturers reduce errors, shorten cycles, and build long-term OEM partnerships grounded in measurable trust and consistent performance.

Engineering Reliability — The Core of Modern OEM Partnerships

Reliability no longer depends on inspection. It’s designed into every stage through simulation, lab validation, and data-driven feedback. Across industries, engineering reliability has become the foundation of trusted manufacturing. It transforms quality from a checklist into a measurable system of assurance.

From my experience working with OEM networks in agri-tech, automobile, and skincare manufacturing, I’ve seen how true reliability is engineered long before a product reaches the market. It begins with three essential practices:

- ISO certifications and quality assurance testing – Standardized procedures that ensure every product, process, and partner meets international benchmarks.

- Transparent data sharing – Real-time access to design validation reports, test results, and audits that create full visibility across the supply chain.

- Predictive maintenance and traceability – AI-driven analytics that forecast wear, detect deviations early, and secure every component’s lifecycle through digital records.

These layers work together to strengthen the design-to-delivery process. When manufacturers share data openly and validate each stage with precision, trust evolves from intent into evidence.

Recent global studies1 confirm that reliability is now a performance metric, not a promise. The best-performing OEM partnerships rely on repeatable systems where performance is predictable, quality is provable, and collaboration is transparent.

Takeaway: Reliability is no longer promised at delivery; it’s engineered through measurable systems that combine ISO compliance, data validation, and proactive transparency—turning modern OEM partnerships into benchmarks of predictable, verifiable trust.

Global Examples of Engineered Trust in Action

Across industries, leading manufacturers are proving how 360° OEM integration drives innovation, speed, and long-term customer confidence. Real trust is built when technology and teamwork operate as one — where OEM partnerships move from transactions to shared performance goals.

- Volkswagen Group – A global benchmark for trusted manufacturing, Volkswagen integrates AI-aided design systems across multiple brands. Its data-driven validation ensures every component performs flawlessly across markets, reflecting a culture of precision and reliability.

- Pioneer India – A strong example of supply chain collaboration. Pioneer co-developed 360° surround-view camera technology directly with automotive OEMs. By embedding safety systems during manufacturing rather than after, the company turned innovation into integrated reliability.

- Sony Entertainment – Beyond electronics, Sony applies the 360° OEM model to design collaboration and after-sales support. Shared R&D platforms allow faster innovation cycles and consistent quality across global product lines.

These examples demonstrate that engineered trust is not about control but coordination. When engineering validation, data systems, and transparent supply chains converge, manufacturers create a feedback loop of continuous improvement.

Takeaway: The most successful OEM partnerships merge human insight with digital precision. Through collaboration, data sharing, and certified reliability, global manufacturers are redefining how trust is built, measured, and sustained.

A Framework to Build Trust in OEM Collaboration

Trust can be engineered through process design, measurable KPIs, and open communication. The most reliable OEM partnerships I’ve seen are those that treat trust not as a feeling but as a system — one built, measured, and improved through structure.

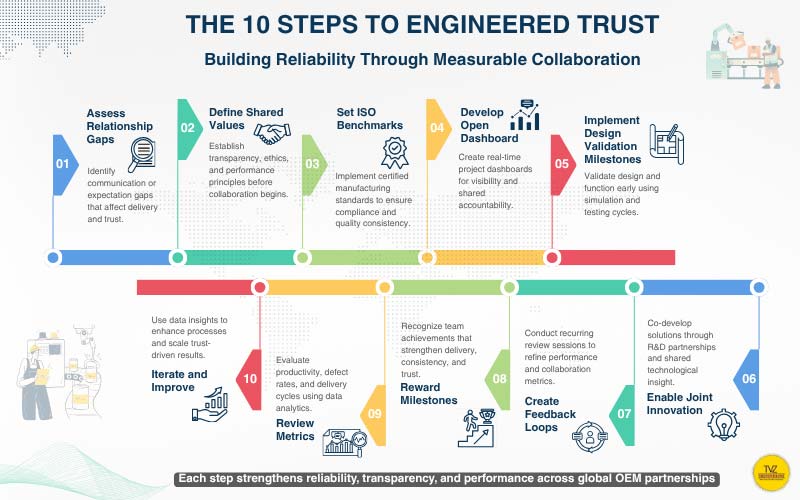

Ten Steps to Engineered Trust

Building engineered trust requires both precision and people. Over the years, while working with global manufacturers, I’ve seen these ten steps consistently deliver results:

- Assess relationship gaps – Identify where communication or expectations fail before they impact performance.

- Define shared values – Align on transparency, quality, and timelines before signing the first contract.

- Set ISO benchmarks – Use certified manufacturing standards to measure compliance and performance across all partners.

- Develop open dashboards – Share project data and validation progress in real time to enhance visibility.

- Implement design validation milestones – Verify functionality early to avoid downstream risk.

- Enable joint innovation – Encourage co-development of new materials, tools, or processes.

- Create feedback loops – Review results frequently to ensure responsiveness and accountability.

- Reward milestones – Recognize achievements that strengthen collaboration and delivery performance.

- Review metrics – Track productivity, defect rates, and lead times across the supply chain.

- Iterate and improve – Use insights from each project to refine processes and scale trust across networks.

Each step reinforces ISO certifications and supply chain collaboration, turning trust into a repeatable practice instead of a one-time outcome.

Piloting Trust Programs

The most effective way to establish this framework is through small, focused pilots. In OEM supply chain models, stakeholder alignment is critical — each partner must understand not just their role but their responsibility for engineering reliability. Data-driven reviews ensure progress remains visible, measurable, and actionable.

Practical Note: Structured trust programs transform intentions into proof. By aligning metrics, sharing insights, and maintaining transparent workflows, OEM partnerships evolve into trusted ecosystems where reliability becomes a shared and verifiable outcome.

India’s 360° OEM Momentum and Manufacturing Excellence

India’s manufacturing story is no longer defined by volume alone. It’s now driven by precision, process maturity, and a growing reputation for credibility that matches the best in global production standards.

The country is rapidly emerging as a global hub for 360° OEM collaboration, blending cost efficiency with compliance, precision, and innovation. I’ve seen this shift firsthand while working with manufacturers who now compete on trust as much as technology.

Key Drivers Behind India’s OEM Momentum:

- Multi-domain certifications: Indian manufacturers are adopting ISO, IATF, and GMP standards across automotive, agri-tech, and skincare industries, aligning local production with global quality systems.

- Export-ready standards: Enhanced testing facilities and validation labs ensure products meet international compliance benchmarks before shipment.

- Design validation capabilities: Digital simulation, material testing, and rapid prototyping have become integral parts of India’s design-to-delivery ecosystem.

- Collaborative innovation: Co-development projects with multinational partners foster shared R&D and sustainable manufacturing solutions.

- Transparency through digitization: Real-time dashboards, traceability tools, and automated audits now define modern Indian production floors.

India manufacturing excellence is built on consistency and openness. Manufacturers aren’t just meeting standards—they’re helping define them.

With certified manufacturing standards and precision engineering at its core, India exemplifies how emerging economies can deliver world-class reliability. Its 360° OEM evolution proves that innovation, quality, and transparency can coexist in every partnership built on trust.

The Future of OEM Partnerships — Trust as a Competitive Advantage

Emerging technologies are redefining how reliability is measured and maintained. Trust is no longer abstract—it’s a data metric that determines credibility in global manufacturing trust. The future of OEM collaboration is being shaped by a new industrial reality—one where data, transparency, and sustainability define success as much as production scale.

As global supply chains evolve, the ability to engineer trust through technology will separate innovators from imitators. Forward-looking manufacturers are already adapting, blending human expertise with digital precision to create ecosystems built on measurable credibility.

In the next decade, manufacturing competitiveness will depend less on cost and more on the credibility of your ecosystem — how trusted, transparent, and technologically integrated your partnerships are— McKinsey & Company

This perspective echoes what several global think tanks have reported: as the industrial landscape becomes more data-driven, trust and transparency2 will define competitiveness more than production capacity ever did.

Key Trends Shaping the Future

The manufacturing landscape is evolving faster than ever. Emerging technologies are rewriting how partnerships function, making trust measurable, sustainability mandatory, and collaboration a shared responsibility across every production ecosystem.

- AI-driven quality checks: Smart inspection systems identify micro-level errors before they impact performance, ensuring consistency across global production lines.

- Blockchain traceability: Digital ledgers verify every transaction, material, and shipment, making the precision manufacturing ecosystem fully transparent and tamper-proof.

- ESG compliance and sustainability: Ethical sourcing, waste reduction, and circular design practices are now key to building long-term reliability and brand value.

- Multi-country resilience: Diversified production networks reduce risk and maintain operational stability during disruptions.

- Data-integrated collaboration: Shared analytics and open communication enable partners to predict challenges and respond faster.

These technologies don’t replace trust—they reinforce it through measurable proof and real-time visibility.

From my marcom experience, I can say, -the future belongs to manufacturers who engineer trust into design, monitor it through data, and sustain it through responsible innovation. In this evolving landscape, reliability isn’t claimed—it’s verified, shared, and built into every OEM partnership.

Also Read:

- Export-Ready Insulation Materials: India’s Global OEM Advantage

- How UPI Payment India Is Driving India’s Digital Payment Boom

FAQ’s: OEM Partnerships

What is the difference between an OEM and an ODM?

An OEM manufactures products based on a client’s design and specifications, while an ODM designs and produces products independently, allowing brands to rebrand and market them under their own name.

How does engineered trust improve manufacturing performance?

Engineered trust enhances performance by integrating design validation, quality testing, and transparent data sharing. It reduces errors, strengthens accountability, and ensures every component meets certified manufacturing standards across the global supply chain.

What role does India play in global OEM innovation?

India is emerging as a leader in 360° OEM innovation, combining ISO-certified production, cost efficiency, and collaborative R&D to deliver precision, compliance, and speed for global manufacturing partners.

How is technology reshaping modern OEM partnerships?

Technologies like AI, IoT, and blockchain enable real-time validation, predictive maintenance, and full traceability, transforming OEM partnerships into data-driven ecosystems that prioritize transparency, reliability, and measurable performance.

Conclusion

Engineered trust has transformed OEM partnerships from transactional exchanges into enduring strategic alliances. The 360° OEM model unites design validation, certified manufacturing standards, and ISO precision to deliver consistency, transparency, and confidence across global operations. It reflects how reliability and innovation now move together, defining competitiveness in every sector.

As global supply chains grow smarter and more interconnected, trust remains the strongest currency in manufacturing. Companies that embed collaboration, certification, and ethical practices into their processes will lead the future of industrial excellence.

At TrendVisionz, we bring together technical, business, and trending insights—delivered with the reliability and trust of experience. Our practical, 360-degree perspective helps businesses navigate change, strengthen partnerships, and achieve sustainable growth in an ever-evolving marketplace.

Additional Resources:

- Deloitte. (2024). The future of manufacturing: Building resilient and trusted supply networks. Deloitte Insights. ↩︎

- McKinsey Global Institute. (2025). The next era of industrial excellence: Trust, technology, and transparency in manufacturing ecosystems. McKinsey & Company. ↩︎

Stay Connected with Me:

Anuj Mahajan is a Mass Communication Specialist, ICF-ACC Certified Coach, Corporate Trainer, Motivational Speaker, NLP Life Coach, Filmmaker, and Author. With 30+ years in media, marketing, and leadership coaching, he unites storytelling, mindfulness, and digital transformation.

- Explore my work: Nuteq Entertainment | TrendVisionz | Author Profile

- Read our newsletters: Transforming Lives | BizTech Chronicle | Nuteq Newsline

- Guest writer: BizCatalyst360 | Praja Today

- Books: Go Mindfulness: Practices for Professionals Coached

- Join the community: LinkedIn Group – Digital Marketing & Content Creation World

- Connect with me: LinkedIn | Twitter | #StoryforBusiness

- Share your review: Leave your review on Google — your feedback helps us grow.

- Listen on Spotify: Leadership Podcast | Guided NLP (7 Episodes) | Daily Motivation – 21 Episodes

Believe. Practice. Perform. Let’s create impact together.

✍️ A Note from the Editor

Independent storytelling thrives with you. Contribute $15/month via PayPal or email us at anujmahajan@trendvisionz.com. [Guest write for us — Free or Paid.]