What if the simplest way to cut industrial energy costs by 25% was hiding in plain sight? Smart insulation and energy efficiency tips are no longer minor details—they are the frontline of future-ready industrial operations. In 2022, industries in IEA member countries collectively spent over USD 1.2 trillion on energy—an increase of nearly 80% compared to 2020. This surge underlines how energy consumption is not only a sustainability challenge but also one of the most significant cost drivers in industrial operations.

Having spent over three decades in broadcast media, business coaching, and digital transformation, I’ve seen how overlooked details often unlock the greatest impact. High temperature insulation, thermal protection, and insulation for boilers and furnaces are such levers—silent yet crucial. They reduce heat loss in furnaces, safeguard workers, and enable sustainable industrial practices.

In this article, we’ll share actionable energy efficiency tips, supported by case studies, data, and insights into why leaders must embrace smart insulation as a strategic choice for the future of industrial energy management.

Also Read:

- Every Layer Counts: Future-Proofing with Multi-Layer Insulation Technology

- Fibre Insulation in Defence: The Backbone of India’s Modern Military Tech

- Types of Insulation Materials and Their Applications: A Complete Guide for Professionals

Why is Energy Efficiency Transforming Industrial Operations?

Industrial operations today cannot ignore efficiency. Rising energy prices, tightening climate policies, and ESG reporting pressure mean efficiency directly impacts survival and competitiveness. The World Bank (2022) notes that energy expenses can consume more than 30% of manufacturing costs, while Statista (2023) reports that industrial processes contribute almost 40% of global CO₂ emissions.

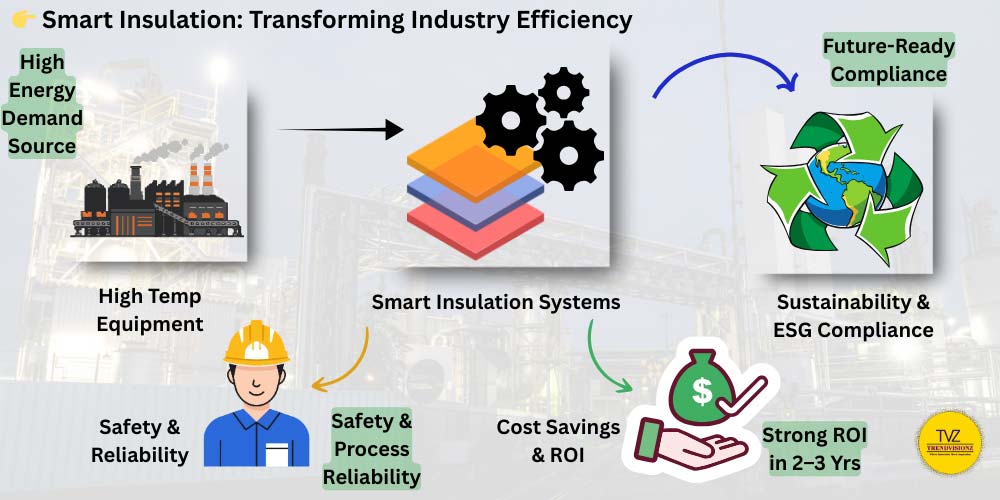

Energy efficiency drives four critical outcomes:

- Reduced carbon footprint aligned with climate commitments.

- Lower operating costs that free capital for innovation.

- Extended equipment life and reduced downtime.

- Stronger corporate image in ESG and sustainability rankings.

Energy efficiency in industrial operations reduces emissions, cuts costs, and builds resilience. With energy consuming up to 40% of budgets, smarter insulation technology provides measurable industrial energy savings while strengthening sustainability credentials and compliance with global standards.

What Role Does Insulation Play in Energy Efficiency?

Insulation is often the unsung hero in industrial energy conservation. Research by the U.S. Department of Energy (DOE) shows that in complex mechanical systems1—like steam distribution networks—energy losses due to poor, missing, or damaged insulation can account for 10% to over 25% of a boiler’s output. This loss can be drastically reduced through targeted insulation upgrades. For instance, a facility with over a mile of steam piping saw thermal losses drop from 15% of boiler load to just 4% after insulating previously uninsulated segments—providing a powerful return on investment with reduced energy waste.

Key benefits of industrial insulation:

- Minimize heat loss or gain across pipelines, boilers, and furnaces.

- Maintain process stability, reducing costly energy spikes.

- Enhance worker safety by lowering surface temperatures.

- Achieve thermal protection for industry and meet strict compliance standards.

Case study: A European petrochemical facility achieved annual savings of over $200,000 by replacing outdated insulation with advanced, high-performance materials. The upgrade reduced energy consumption by minimizing heat transfer, lowered utility costs, and improved long-term operational efficiency.

Mr. Prashant Goel, Co-Founder of PBM Insulations, explains:

“Smarter insulation is a high-ROI investment. By cutting heat loss, stabilizing processes, and protecting workers, insulation systems transform hidden inefficiencies into measurable energy savings and long-term compliance.”

This example highlights how insulation upgrades deliver not only immediate financial savings but also strategic advantages in sustainability, competitiveness, and compliance—making them essential for forward-looking industrial operations.

How Are Insulation Systems Becoming Smarter?

The evolution of insulation is no longer about thickness—it’s about intelligence. Innovations blend materials, IoT, and sustainability.

Material innovations:

- Aerogels: Ultra-thin, highly effective, used in aerospace and oil refineries.

- Reflective coatings: Minimize radiant heat in extreme conditions.

- Hybrid composites: Durable and thermally resistant for heavy industry.

Smart monitoring:

IoT-enabled insulation integrates sensors that track heat loss, identify wear, and predict failures, reducing downtime.

Sustainable manufacturing:

Technical insulation is projected to grow to USD 13.4 Bn by 2028. The increase at a CAGR of 5.3% driven by regulations, oil and gas demand, and industrial adoption.

Insulation is evolving into a fusion of smart technology and sustainable materials. With IoT sensors and recyclable composites, industries operate leaner, greener, and smarter—turning insulation into a tool for predictive efficiency.

How Do Different Industries Use Smart Insulation?

Every sector applies insulation differently, but the results point to the same benefits: cost savings, compliance, and safety.

- Manufacturing: Reduces electricity use, stabilizes production costs.

- Food processing: Maintains temperature integrity for safety and quality.

- Pharma & healthcare: Supports cleanroom standards and reduces contamination risks.

- Energy & chemicals: Enables high-temperature efficiency and reduces emissions.

- Retail & cold storage: Cuts HVAC loads, extending shelf life for perishables.

- Education: School upgrades to insulation save up to 20% in energy use (IEA, 2021).

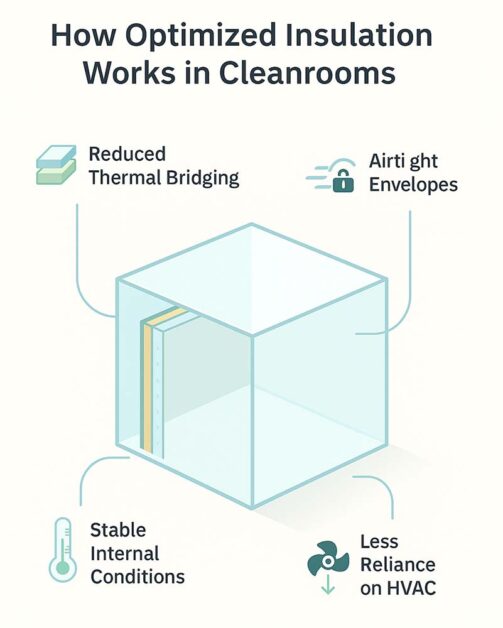

Case Study: Optimized Insulation in Indian Pharma Cleanrooms

An Indian pharmaceutical company reduced HVAC energy consumption by 18% while maintaining stringent cleanroom standards. This aligns with findings from Italian energy audits, which highlight that HVAC systems account for over 60% of pharmaceutical energy use2.

How Optimized Insulation Works in Cleanrooms

- Reduced Thermal Bridging: Eliminates heat escape points.

- Airtight Envelopes: Prevents outside air infiltration.

- Stable Internal Conditions: Minimizes HVAC load fluctuations.

- Less Reliance on HVAC: Cuts energy demand while maintaining compliance.

This case proves that smart insulation directly improves energy efficiency in highly controlled environments, helping pharmaceutical manufacturers achieve operational savings, regulatory compliance, and sustainable industrial practices without compromising cleanroom integrity.

Smarter insulation is cross-industry and scalable. From hospitals to cold storage, it strengthens compliance, saves costs, and ensures process reliability across manufacturing, healthcare, energy, and education sectors.

What Stops Industries from Adopting Smart Insulation?

Many industries still hesitate to adopt smart insulation. The benefits are clear, but concerns remain. Some common concerns often hide the proven ROI and long-term savings these systems deliver.

- High upfront costs: Yet McKinsey (2023) shows average ROI of 150% with payback in 2–3 years.

- Installation downtime: Modern prefabricated solutions reduce disruption.

- Awareness gaps: Decision-makers underestimate hidden energy losses.

Solution: Partnering with expert providers who combine technical depth and sustainability strategy accelerates adoption.

Adoption barriers are more perception than reality. ROI, modern solutions, and expert partners show that insulation upgrades deliver rapid payback, minimal downtime, and lasting competitive advantages.

What Does the Future Hold for Industrial Insulation?

Insulation is shifting from an engineering detail to a boardroom priority. Governments are tightening efficiency standards, and shareholders expect measurable ESG compliance. Industry experts forecast it as one of the fastest-growing industrial sustainability solutions.

Early adopters will:

- Lead global sustainability rankings.

- Minimize risks from volatile energy markets.

- Achieve long-term operational resilience and profitability.

The future of industrial insulation is strategic. As sustainability regulations and ESG pressure grow, smarter insulation positions businesses as leaders—ensuring resilience, profitability, and sustainable operations in a competitive landscape.

Also Read:

- Reimagining Insulation: Industry Trends Shaping Future of EVs and Defence

- PAN 2.0 Explained: How India’s Tax Identity System Is Going Fully Digital

FAQ: Energy Efficiency Tips

How quickly can industries recover smart insulation costs?

Most industries recover costs within two to three years. Energy savings, reduced downtime, and extended equipment life create a strong ROI, making insulation upgrades one of the fastest-returning industrial sustainability solutions.

Can smart insulation help with ESG compliance?

Yes. Smart insulation reduces energy use, lowers emissions, and improves workplace safety. These outcomes directly support ESG reporting requirements, align with sustainability commitments, and strengthen a company’s reputation with regulators, investors, and environmentally conscious customers.

Is insulation technology only for large industries?

No. Small and medium enterprises also benefit. Whether in food processing, logistics, or manufacturing, optimized insulation reduces operating costs, improves efficiency, and provides thermal protection, delivering competitive advantages and long-term sustainability for all business sizes.

Conclusion

Energy efficiency in industrial insulation is now a strategic necessity, not an option. By reducing heat loss, stabilizing processes, and supporting sustainable industrial practices, smart insulation strengthens both competitiveness and compliance. The evidence is clear—industries that invest in smarter insulation achieve measurable savings, improved safety, and long-term resilience.

The time has come for CEOs, founders, and decision-makers to treat insulation as a boardroom priority. Choosing smart insulation today means building future-ready industrial operations that can withstand rising energy costs, stricter regulations, and growing ESG pressures.

At TrendVisionz, we believe innovations like smart insulation are more than technical upgrades—they are catalysts for sustainable growth. By spotlighting energy efficiency tips and industry best practices, our goal is to help leaders make informed, future-ready decisions that drive resilience, compliance, and lasting impact.

Additional Resource:

- Moshood Akanni Alao, Olawale Mohammed Popoola, Temitope Raphael Ayodele (2022). Waste-to-energy nexus: An overview of technologies and implementation for sustainable development. Cleaner Energy Systems, 3, 100034. ↩︎

- Bruni, G., Martini, C., Martini, F., & Salvio, M. (2023). On the Energy Performance and Energy Saving Potential of the Pharmaceutical Industry: A Study Based on the Italian Energy Audits. Processes, 11(4), 1114. https://doi.org/10.3390/pr11041114 ↩︎

Stay Connected with Me:

Anuj Mahajan is a Mass Communication Specialist, ICF-ACC Certified Coach, Corporate Trainer, Motivational Speaker, NLP Life Coach, Filmmaker, and Author. With 30+ years in media, marketing, and leadership coaching, he unites storytelling, mindfulness, and digital transformation.

- Explore my work: Nuteq Entertainment | TrendVisionz | Author Profile

- Read our newsletters: Transforming Lives | BizTech Chronicle | Nuteq Newsline

- Guest writer: BizCatalyst360 | Praja Today

- Books: Go Mindfulness: Practices for Professionals Coached

- Join the community: LinkedIn Group – Digital Marketing & Content Creation World

- Connect with me: LinkedIn | Twitter | #StoryforBusiness

- Share your review: Leave your review on Google — your feedback helps us grow.

Believe. Practice. Perform. Let’s create impact together.

✍️ A Note from the Editor

Independent storytelling thrives with you. Contribute $15/month via PayPal or email us at anujmahajan@trendvisionz.com. [Guest write for us — Free or Paid.]

6 comments

[…] Posts Smart Insulation and Energy Efficiency Tips for Industry How Social Media Killed Age-Appropriate Dressing How Digital Marketers Can Leverage Alternative […]

Excellent breakdown, I completely agree with the challenges you described. For our projects we started using an AI-driven system called AI link building by OptiLinkAI, and it has simplified the entire process. It’s refreshing to see technology finally making link acquisition smarter, not just faster.

thanks for ur feedback

You’ve made this topic so simple.

Its like you read my mind You appear to know a lot about this like you wrote the book in it or something I think that you could do with some pics to drive the message home a little bit but instead of that this is fantastic blog An excellent read I will certainly be back

practical insights on implementation, readers can explore Smart Insulation and Energy Efficiency Tips for Industry

Comments are closed.